#cable stayed suspension bridge

Explore tagged Tumblr posts

Text

Cable Stayed Bridge - Types, key features and construction

A cable stayed bridge is a modern engineering marvel known for its strength, efficiency, and aesthetic appeal. It uses one or more towers to support the bridge deck through a series of cables, which transfer the load directly to the foundation. Unlike suspension bridges, the cables in a cable stayed bridge connect directly from the deck to the towers in a straight line. This design provides…

#bridges#cable stayed bridge construction#cable stayed bridge design example#cable stayed bridge images#cable stayed bridge surat#cable stayed bridge types#cable stayed railway bridge in india#cable stayed suspension bridge#extradosed bridge vs cable stayed bridge#travel

0 notes

Text

1 note

·

View note

Text

Brooklyn Bridge, New York, United States: The Brooklyn Bridge is a hybrid cable-stayed/suspension bridge in New York City, spanning the East River between the boroughs of Manhattan and Brooklyn. Opened on May 24, 1883, the Brooklyn Bridge was the first fixed crossing of the East River. Wikipedia

196 notes

·

View notes

Note

The party has to cross a bridge to reach the castle supposedly guarded by a dragon. Except the bridge IS the dragon. The dragon closely resembles a cable-stayed suspension bridge when dormant.

292 notes

·

View notes

Text

youtube

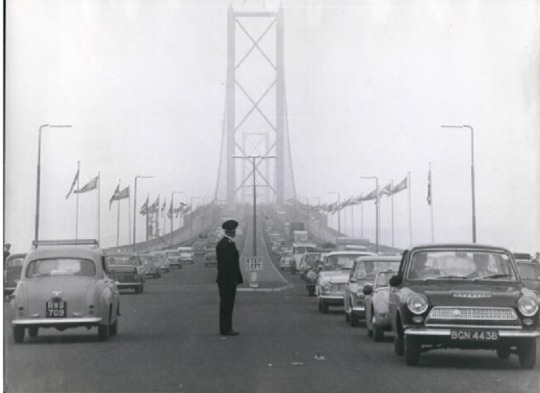

On September 4th 1964 the Forth Road bridge was officially opened to the public.

Soldiers of Lowland regiments from the south linked up symbolically with a Highland brigade from the north to mark the opening of the new crossing, which cuts more than an hour off the journey-time by road.

The Forth Road Bridge at the time the fourth longest in the world. The opening of the Forth Road Bridge marked end of the Ferries across the Forth an 800-year-old service.

At its peak, the service was running 40,000 trips a year, carrying 1.5m people. The four ferryboats have been run by 70 men only 30 of whom were be re-employed on the new bridge collecting tolls. Up to 400 men have worked on the bridge sometimes in very dangerous conditions with winds up to 100mph. Seven men lost their lives - others were saved by the terylene safety nets suspended beneath them. It took 39,000 tons of steel, 30,800 miles of wire in the suspension cables, and is 163ft above the river at its highest point. Tragically 7 workers died during the construction, although another source says only 3 died.

53 years later, to the day the official opening of The new Queensferry Crossing takes place today. The structure spans 1.7 miles (2.7km) making it the longest three-tower, cable-stayed bridge in the world. Another record was set when in 2013 they had the largest continuous underwater concrete pour over 14 days the 24-hour non-stop operation successfully poured 16,869 cubic metres of concrete into the water-filled south tower caisson.The building work was also hit by tragedy with the death of one worker..

While we remember the building of these bridges we also remember those who died on three structures that cross the Firth of Forth.

13 notes

·

View notes

Text

The cable-stayed Aomori Bay Bridge (1994) with its A-shaped suspension towers is a distinctive feature of Aomori, Japan. A floating pedestrian bridge is below.

2 notes

·

View notes

Text

September 24, 1973

The guy working at the desk at his hotel only speaks a little English, but they communicate well enough for him to write down the address of the train station on a piece of paper. Daniel rubs at the back of his neck, twitchy and impatient, even though the sun is up.

Slept a little bit. Kept some food down, but he’s uncomfortably bloated now. He shifts his weight as he waits for the concierge to call him a taxi, and can’t remember when was the last time he fucking took a shit.

Hates his fucking body all of a sudden.

A few minutes later he’s outside, lighting a cigarette and leaning against the wall of the hotel as he waits for the taxi. Closing his eyes against the sun, feeling the warmth on his face. It feels good, even though he’s beginning to resent it. Feels safe. He could fall asleep, just like this, standing up.

He digs Lestat’s watch out of his pocket again, flips it open. Ornate thing. Antique. He tries to wind it but nothing happens, and he can’t help wondering when it stopped. It’s stuck on 3:59.

Maybe if things calm down, if he thinks he can stay in one place for a few days, he can get someone to fix it.

Lestat is still down there, Daniel thinks. He pictures it, wonders if Lestat sleeps curled up like a person, on flat on his back like a corpse. He thinks of that fucked up house and all those books, and has so many questions to ask.

The taxi driver speaks even less English than the concierge, but Daniel is able to show him the note. Friendly as he nods, and gestures towards the trunk, but Daniel keeps his bag with him, in his lap in the back seat, hugging it as they pull out.

He slumps against the door, his temple leaning into the window. The driver has talk radio on and Daniel can’t make out a word of it, which is… relaxing. Sun beats down through the glass, baking him. Feels safe. Moving, in the sun. Warm now.

Eyes close. Too tired to be scared. He’s not sure how far away the train station is, but maybe it’s okay to sleep for the car ride.

Armand knew that Louis would kill all those other vampires. They’re people, Daniel wants to scream. He can imagine himself down there, beneath the theatre, holding the yellow dress. They’re still people. The image of the theater is so vivid now, knowing what Armand looks like. Shorter than he imagined, but he holds the entire room hostage with his presence.

Daniel doesn’t understand why Louis stayed with him.

He killed your wife. She was your daughter.

The taxi hits a bump and Daniel gasps awake.

Unsure where he is, can’t remember anything except he’s got to get away, keep moving moving moving. The sky is too open through the window, and he can see water, and the cables of a suspension bridge blurring by. He sits up, rubbing at his chest, feeling his heart racing through his t-shirt.

He’s back in San Francisco. On the Golden Gate. Louis’s voice spills from the car radio.

Daniel shouts. He tells the driver to stop, but the man just glances at him in the rearview, perplexed. No English. Daniel’s hand leaves a smudge on the window and he considers throwing himself out of the car.

“They’ll find me here,” he shouts. “I left California, Louis will know. They’ll find me, they’ll know!!”

The driver slows. Not to stop, but to adjust to the flow of traffic. He snaps at Daniel in Portuguese, and his ears ring.

Armand is gonna fucking kill me.

He’s sweating, reaching for the door handle, but as the car slows he gets a better look at the outside.

Red bridge but… it’s not San Francisco. It’s not. It’s not.

He turns around in the seat, looking out the back window. Doesn’t see the skyline. His stomach cramps and his vision doubles.

“Sorry,” he mumbles. Lip quivering. He twists back to sit correctly. Hugs his bag to his chest. The driver narrows his eyes, and Daniel holds up his hands in apology. “Sorry,” he says again. He doesn’t know any Portuguese but he attempts a quick “Lo siento,” just in case.

Their eyes stay locked for a moment. Finally the driver nods. He shrugs, mutters to himself. Looks back to the road.

Daniel tilts his head against the glass, trying to see up to the top.

Just a red bridge. He’s in Lisbon. He remembers that. He flew to Lisbon.

He’ll take a train next. Just take off into Europe and see what happens. Trains don’t seem safer but he wonders if he should try take one overnight. That way he can keep moving. Won’t have to stop.

That guy told him about the Midnight Sun one time. It’s almost winter, though, it’s not going to work. In fact, it would be the opposite soon. Dangerous.

Anyway. That guy got locked up, he was crazy.

Daniel isn’t crazy.

[previous day] | [next day]

#vamptember#vamptember 1973#daniel molloy#vampire chronicles#stuff i wrote#GOOGLE THE 25 DE ABRIL BRIDGE IN LISBON I LEARNED ABOUT IT WHILE RESEARCHING I HAD NO IDEA!#very excited about this !

13 notes

·

View notes

Text

.

New York - Day 2

Walking across the Brooklyn Bridge between Manhattan and Brooklyn.

The Brooklyn Bridge is a hybrid cable-stayed/suspension bridge in New York City, spanning the East River between the boroughs of Manhattan and Brooklyn. Opened on May 24, 1883, the Brooklyn Bridge was the first fixed crossing of the East River. It was also the longest suspension bridge in the world at the time of its opening, with a main span of 1,595.5 feet (486.3 m) and a deck 127 ft (38.7 m) above mean high water. The span was originally called the New York and Brooklyn Bridge or the East River Bridge but was officially renamed the Brooklyn Bridge in 1915.

A major tourist attraction since its opening, the Brooklyn Bridge has become an icon of New York City. The Brooklyn Bridge is designated a National Historic Landmark, a New York City landmark, and a National Historic Civil Engineering Landmark.

2 notes

·

View notes

Text

ON THIS DAY:

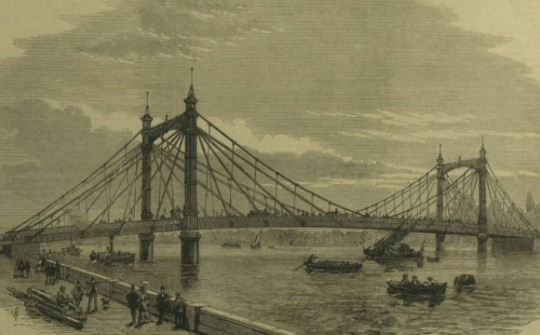

150 years ago (23 August 1873), the Albert Bridge, which connects Chelsea to Battersea, was opened for the first time.

Here it is depicted by the Illustrated London News, 30 August 1873.

—

Albert Bridge is a road bridge over the River Thames connecting Chelsea in Central London on the north bank to Battersea on the south.

Designed and built by Rowland Mason Ordish in 1873 as an Ordish–Lefeuvre system modified cable-stayed bridge, it proved to be structurally unsound.

Between 1884 and 1887, Sir Joseph Bazalgette incorporated some of the design elements of a suspension bridge.

In 1973, the Greater London Council added two concrete piers, which transformed the central span into a simple beam bridge.

As a result, the bridge is an unusual hybrid of three different design styles. It is an English Heritage Grade II* listed building.

#Engineering History#London History#Albert Bridge#Chelsea#Battersea#Illustrated London News#Rowland Mason Ordish#Sir Joseph Bazalgette#Greater London Council

6 notes

·

View notes

Text

UNDERSTANDING ....looking towards the Brooklyn Bridge NY

The Brooklyn Bridge is a hybrid cable-stayed/suspension bridge in New York City, spanning the East River between the boroughs of Manhattan and Brooklyn. Opened on May 24, 1883, the Brooklyn Bridge was the first fixed crossing of the East River.

8 notes

·

View notes

Text

Hehehe, the startup costs to start a new, healthy behavior are BIG (i.e. pushing a boulder up a 70-degree incline big).

Even if your old behavior (i.e. alcoholism, smoking, neglecting your health) is killing you slowly, it’s less painful in the moment than facing them biiiig painful startup cost of pushing that boulder up the hill.

But,

Eventually,

You work up the nerve to bite the bullet. Maybe you lose a friend, or get diagnosed, or need 10 cavities filled.

You start pushing the boulder up the hill because you’re afraid to die, and You’re afraid to be stuck at the bottom of the hill forever.

So You go to an AA meeting, you bodydouble on that project, you buy a new electric toothbrush, and you resolve to go outside more.

And with every push, your muscles scream as gravity beckons you back to that rut at the bottom of the hill, that familiar devil of a slow, grey death.

But with a Herculean strength, you keep going. You can’t see the top of the hill, the boulder’s in the way, but you’re sure it must be close.

You keep going.

You’re one year sober, finals are coming up and you’ve got straight A’s, you’ve been going to the gym for 6 months straight, you watch the seasons change with friends instead of from your window. You forget what it’s like to not be under the boulder’s weight. You forget what it’s like when your muscles aren’t pulled taut like suspension bridge cables.

And then your toe touches the top of the hill. And you’re too exhausted. You imagine relief. You imagine life like it was at the bottom of the hill- familiar, easy, not constantly fighting gravity’s jabs.

Then the boulder slips. It flattens you, drags you back down the hill like an uncaring wave. And for all your effort and pain, you remember that you’re small and human.

You have one drink at a graduation and go on a binge. Your dog dies and you don’t go outside for six months -you yell at your friends when they try to make you. You oversleep for that first final and out of shame skip the rest.

Now you’re at the bottom of the hill again. Your wounds knit well enough after the first month, but your hard earned muscles wither the more you look at the hill, the more you look at the boulder, the more you remember the pain of pushing and the pain of falling from grace.

If you stay at the bottom, you think, there’s less height to fall.

Then another tooth falls out, and you get scared of being 6 ft under. You decide to push the boulder up the hill again.

The cycle repeats for years. It will repeat until pushing the boulder becomes the same to you as living at the bottom of the hill. Or it will repeat until you build a house in the hill’s shadow. It may repeat until you’re dead.

But we are not Sisyphus. With every fall we get up from, our muscles grow stronger. For every day we take it slow and only push the boulder an inch, we gain enough breath to continue.

We are not Sisyphus.

The top of the hill is real and the boulder can be pushed there. You can go 10 years sober, You can only need to see your therapist twice a year, you can run the marathon with your close friends.

We are not Sisyphus, and when we finally push the boulder over the final ridge, the incline lessens, our muscles are strong, and we build a home out of the stone we carried.

On the mountain’s peak, we live in sunlight. And though we’ll end up 6ft under someday no matter what, though we have scars, it was worth it for the cool mountain streams, for the friends and warm earth that was waiting for us. It’s easy here, just like the bottom of the hill, but now there’s more time. There’s more people, and the world has color again.

The Sisyphean era has come to an end.

I'm in my sisyphus era but I'm pretty sure I'm almost out of it

55K notes

·

View notes

Text

Turnbuckle: Essential Tool for Tensioning and Securing

Abstract

In various industries, from construction to marine, there is a need for secure and reliable tensioning systems. The device that serves this purpose, often overlooked, is an essential component for a wide range of applications: the tensioning tool. These tools are designed to apply controlled tension to cables, wires, and ropes, ensuring they remain in place without shifting or slackening. They provide a crucial link in securing structures, rigging, and other essential components, making them indispensable for safety and efficiency in several professional fields.

Understanding the Tensioning Mechanism

At its core, a tensioning device operates on a simple mechanical principle. It consists of two threaded bolts with opposing directions, a central body to hold them together, and a mechanism that enables easy adjustment of the tension applied to the connected cables or wires. The device functions by rotating these bolts, which either extend or retract, thus increasing or decreasing the length of the device. This action, in turn, tightens or loosens the cable or wire it is connected to, allowing for precise control over the tension applied.

This method is beneficial in various applications because it ensures that wires and cables maintain their desired tension, which is essential for structural integrity. Whether it’s holding up a fence, securing cables in a rigging system, or stabilizing a marine vessel’s rigging, this tool plays a crucial role in maintaining safety, functionality, and durability.

Applications of the Tensioning Tool

1. Construction

In the construction industry, these devices are essential for ensuring that structures remain stable and safe during and after construction. When setting up scaffolding or securing cables, it is important to control the tension carefully. Too much tension can cause the structure to be overly stiff, potentially leading to stress points and breakage. On the other hand, insufficient tension can cause the cables to slacken, compromising the safety and stability of the structure. These devices are often used to tension cables, support beams, and other key structural components, ensuring that each component is set at the correct tension for maximum safety.

2. Marine Applications

In the marine industry, such devices are particularly useful for rigging sailboats and securing the masts. The tension in the rigging needs to be precise, as it ensures that the sails can be adjusted effectively without causing damage to the structure or the vessel’s stability. Over-tightening can lead to breakage, while too little tension can make the sails ineffective and unmanageable. Whether for larger vessels or smaller sailing boats, these tools are instrumental in setting up the rigging properly. They can also be used in the maintenance of mooring lines or securing ropes that hold boats in place.

3. Fencing and Signage

Tensioning tools are also widely used in fencing applications, particularly when installing wire or chain link fences. The wires need to be kept taut to maintain the structure’s integrity. Without adequate tension, the fence can sag over time, leading to an unattractive appearance and potential security issues. These tools ensure that the wire stays taut, preventing it from loosening or bending and maintaining the fence's overall strength. Similarly, they are useful in securing signage in place, ensuring that banners or other large signs stay securely fastened without the risk of flapping or tearing.

4. Bridge Construction and Tensioned Cables

For larger infrastructure projects, like bridges and skyscrapers, tensioning devices play a critical role in maintaining the integrity of the cables that hold up such structures. The tension in suspension bridge cables, for example, must be calibrated precisely to ensure that the structure is stable and able to carry loads without putting too much stress on any individual cable. The tensioning device allows for minute adjustments, ensuring the cables are neither too tight nor too loose, creating the necessary balance for structural strength.

Types of Tensioning Tools

Tensioning tools come in several types, each suited to specific tasks and needs. The most common types include:

1. Manual Devices

Manual tensioning tools are the most basic and cost-effective types. These tools often use a screw mechanism or a ratcheting mechanism to adjust the tension applied to the wire or cable. They are usually lightweight and portable, making them ideal for smaller, less heavy-duty applications. These tools are commonly used in smaller construction or rigging projects, such as fencing or securing cables on smaller boats. Despite their simplicity, they offer adequate precision and reliability for most small-scale tasks. For businesses or individuals seeking reliable equipment for tensioning, a turnbuckle equipment supplier in UAE can provide the necessary tools and expertise. When purchasing from a trusted turnbuckle equipment supplier in UAE, you ensure access to high-quality products that meet your specific tensioning needs.

2. Hydraulic Tools

For larger, more heavy-duty projects, hydraulic tensioning tools are often used. These tools apply pressure via hydraulic force, allowing for much greater tensioning force than manual tools can provide. Hydraulic tensioning tools are used in applications where large cables or structures need to be adjusted, such as in bridge construction or large-scale rigging projects. The advantage of hydraulic tools is that they offer a more consistent and powerful tensioning force, making them suitable for heavy-duty applications.

3. Electric Tensioners

Electric tensioners are used in high-volume applications where speed and efficiency are critical. These tools use electric motors to adjust the tension on cables and wires, which can significantly speed up the process when large amounts of wire need to be tensioned quickly and precisely. Electric tensioners are commonly found in industrial settings and are often used in production lines or during large construction projects where rapid installation of tensioned cables is necessary.

Benefits of Proper Tensioning

Using the right tensioning tool for the job brings a variety of benefits, ensuring that each application is performed with precision and reliability.

1. Safety

The most important benefit of using a tensioning tool is safety. Properly tensioned cables and wires reduce the risk of structural failure, which could otherwise lead to accidents, equipment damage, or even injury. Whether in a construction project or when securing a boat’s rigging, ensuring that cables are at the correct tension helps prevent accidents and maintains the stability of the entire system.

2. Durability and Longevity

When tension is applied correctly, the longevity of the materials is extended. Over-tightened cables can become damaged or brittle, while too much slack can lead to wear over time. Proper tensioning minimizes wear and tear on the materials, ensuring they last longer and perform more effectively.

3. Improved Performance

Whether it's the tension in a bridge’s cables or a boat’s rigging, proper tension ensures that each system works as efficiently as possible. Properly tensioned cables help maintain the desired balance and performance, whether it's the stability of a structure or the functionality of a system.

Conclusion

The tensioning tool is a crucial device across a variety of industries, offering control and precision for a wide range of tasks. Whether in construction, marine applications, fencing, or large infrastructure projects, these tools ensure that cables and wires are securely held in place, preventing accidents and wear. Turnbuckles are a key component in many of these applications, providing the necessary tension to secure cables and wires effectively. With options ranging from manual devices to hydraulic and electric tensioners, there is a tool for every application. By understanding the importance of tensioning and selecting the appropriate tool for the job, professionals can ensure that their systems remain stable, safe, and efficient for years to come. The use of turnbuckles in various industries helps maintain proper tension, ensuring structural integrity and safety in all applications.

0 notes

Text

youtube

The Insane Future of Bridge Construction Explore the incredible process behind constructing modern-day bridges! In this video, we uncover the advanced engineering, cutting-edge technology, and meticulous planning that goes into building these architectural marvels. From designing and laying foundations to assembling and finishing, learn how these structures connect the world in the most efficient and durable ways possible. Whether it's suspension bridges, cable-stayed designs, or massive overwater constructions, discover the techniques that make them withstand time and the elements. This is a must-watch for engineering enthusiasts, aspiring architects, and anyone curious about modern infrastructure. What’s your favorite bridge in the world? Let us know in the comments below! If you enjoyed this video, give it a thumbs up 👍, share it with your friends, and subscribe to our channel for more fascinating insights into modern construction. Don’t forget to hit the bell 🔔 to stay updated on our latest content! #HowBridgesAreMade #ModernBridges #BridgeEngineering #ConstructionTechnology #EngineeringMarvels #Infrastructure #CivilEngineering #BridgeConstruction #ModernArchitecture #StructuralEngineering Disclaimer: This video is for informational and entertainment purposes only and does not constitute professional advice. via ManufacTour https://www.youtube.com/channel/UC7jM-HeXkReUyl3y6oSU-3w December 21, 2024 at 06:00AM

#digitalmanufacturing#ai#manufactour#techinnovation#manufacturing#materialsscience#automotive#futuretech#Youtube

0 notes

Text

Hangers, Bridges and Large Structures

Hangers, Bridges, and Large Structures: The Triumph of Engineering and Innovation

When it comes to large-scale infrastructure, hangers, bridges, and other monumental structures are prime examples of human ingenuity and engineering excellence. These towering constructions are not only functional but often serve as symbols of technological progress, showcasing the incredible feats of architecture and design. Whether supporting immense loads, connecting distant places, or standing as architectural marvels, these structures are integral to modern life, transforming the way we travel, work, and interact with the world.

Hangers: A Critical Part of Infrastructure

In the context of large-scale structures, hangers are specialized buildings or frameworks used primarily to house and protect large equipment, such as aircraft, ships, or machinery. These vast enclosures, often seen in airports and shipyards, are designed to provide ample space for maintenance, repairs, and storage.

Aircraft Hangers

Perhaps the most iconic form of hangers are those built for aircraft. Airplanes, whether commercial or military, require large spaces for maintenance and protection from the elements. Aircraft hangers are engineered to accommodate the size of these massive machines while allowing enough room for ground crews to perform maintenance tasks efficiently. These hangers are often equipped with high ceilings, wide doors, and specialized equipment to ensure the safe handling of aircraft.

The design of aircraft hangers also incorporates safety features such as fire suppression systems and reinforced structures to withstand extreme weather conditions. Innovations in lightweight materials and energy-efficient designs are becoming more common, as the aviation industry seeks to balance function with sustainability.

Shipbuilding Hangers

Shipbuilding hangers, located in shipyards, serve a similar purpose, providing an area for the construction, repair, and storage of ships. These structures are even larger than their aviation counterparts, as ships vary greatly in size, from small boats to massive ocean liners. Steel frames, high overhead cranes, and concrete floors are often used in these hangers to support the immense weight of ships and the heavy machinery used during construction.

Bridges: Connecting People and Places

Bridges are among the most significant and visible forms of large-scale structures. They provide vital connections across rivers, valleys, and other natural obstacles, enabling the free flow of people, goods, and services. A well-designed bridge does not just serve its functional purpose but often becomes an icon of engineering prowess, standing the test of time and enduring harsh environmental conditions.

Types of Bridges

Suspension Bridges: Suspension bridges, like the iconic Golden Gate Bridge, are among the most impressive feats of civil engineering. These bridges feature large cables suspended between towers, with the bridge deck hanging below them. The weight of the deck is transferred through the cables, which allows the bridge to span great distances over water or valleys.

Arch Bridges: Arch bridges use a curved structure to transfer weight efficiently to the supports at either end. They are known for their aesthetic appeal and can be found in both ancient and modern engineering projects. These bridges are often used to cross rivers, ravines, and other natural obstacles.

Cable-Stayed Bridges: In a cable-stayed bridge, cables run directly from the deck to one or more towers. This type of bridge is ideal for medium to long spans and can be built with fewer materials compared to suspension bridges.

Beam Bridges: The simplest type of bridge, beam bridges, rely on horizontal beams supported by pillars at either end. Though simple, beam bridges are incredibly effective and can be found across highways, railways, and rivers.

The Engineering Behind Bridges

Designing and constructing a bridge is a meticulous process that requires careful consideration of the environment, load requirements, and materials used. Bridges must be engineered to withstand weather extremes, such as high winds, heavy rains, and even earthquakes. They are built to endure the weight of vehicles and pedestrians while also factoring in dynamic forces, like the sway of wind or movement of traffic.

Materials such as steel, concrete, and composite materials are commonly used in bridge construction, chosen for their strength and durability. Modern innovations, such as the use of smart sensors, allow engineers to monitor the health of bridges, detecting stress points or wear over time and ensuring the safety of users.

Large Structures: The Heart of Modern Infrastructure

Beyond hangers and bridges, large structures are the cornerstone of many industries, from manufacturing to energy generation and transportation. These structures are designed to carry out specific functions, often involving massive machinery, vast amounts of materials, or extensive operations.

Power Plants and Industrial Complexes

Power plants and large industrial complexes are among the most imposing structures in the world. These facilities house machinery that generates electricity, refines oil, or processes chemicals. Their size and scale demand meticulous planning and design, as they often operate 24/7 in demanding environments. Cooling towers, large turbines, and energy-efficient systems are common features of these structures, designed to keep operations running smoothly while minimizing environmental impact.

Skyscrapers and Towers

Modern cities are defined by their skyline, often dominated by towering skyscrapers and communication towers. These structures, which can reach heights of hundreds of meters, are built using innovative construction techniques and materials. Steel and reinforced concrete provide the structural integrity needed to support the immense weight and wind pressure these buildings face.

Skyscrapers, in particular, push the limits of engineering, incorporating elevators, energy-efficient systems, and earthquake-resistant features. These buildings are not just functional but also serve as symbols of urban development and modernity.

Innovations Shaping the Future

As technology advances, so too do the materials and methods used in building hangers, bridges, and large structures. Modern innovations in 3D printing, robotic construction, and sustainable design are allowing engineers to build more efficiently, with fewer resources, and with a reduced environmental footprint.

For example, modular construction enables parts of a bridge or structure to be pre-built and then assembled on-site, reducing construction time and costs. Likewise, smart infrastructure, which integrates sensors and data analytics, is helping monitor the health of these structures, predicting maintenance needs and preventing failures before they occur.

Conclusion

Hangers, bridges, and large structures are much more than mere buildings—they are the lifeblood of modern society, connecting us to the world around us, providing essential services, and symbolizing the remarkable achievements of engineering and design. Whether they are enabling global travel, supporting industries, or providing critical infrastructure, these structures are a testament to human ingenuity and the relentless drive to overcome challenges and shape a better future.

0 notes

Text

Wire rods are fundamental components in numerous industries, playing a crucial role in applications ranging from construction and automotive to manufacturing and beyond. Their versatility, strength, and adaptability make them indispensable in the modern industrial landscape. In this article, we explore the significance of wire rods, their diverse applications, and the reasons behind their widespread use in various sectors.

What Are Wire Rods?

Wire rods are long, cylindrical steel products produced through hot rolling processes. They are typically supplied in coil form and are further processed to create wire and other finished products. The composition of wire rods can vary, including low carbon, medium carbon, high carbon, and alloy steel grades, each tailored for specific applications based on their mechanical properties.

Applications of Wire Rods

Wire rods find utility in a wide array of industries due to their flexibility and strength. Here are some key applications:

Construction Industry

Reinforcement Bars: Wire rods are processed into rebars used to reinforce concrete structures, providing tensile strength and stability to buildings, bridges, and other infrastructure.

Wire Mesh: Used in construction for fencing, partitions, and safety nets, wire rods are fabricated into wire mesh, which adds structural integrity and security to various projects.

Automotive Industry

Tire Bead Wires: Wire rods are essential in manufacturing tire bead wires, which help maintain the shape of the tire and ensure it stays securely mounted on the wheel rim.

Suspension Components: High-strength wire rods are used to create suspension springs and other components that absorb shocks and maintain vehicle stability.

Manufacturing and Engineering

Fasteners: Wire rods are drawn into wires to produce bolts, nuts, screws, and other fasteners essential for assembling machinery, appliances, and structures.

Cables and Wire Ropes: Wire rods are twisted into cables and wire ropes used in various lifting, towing, and securing applications.

Agriculture

Fencing: Wire rods are used to produce durable fencing materials that withstand environmental conditions, ensuring the safety and security of livestock and crops.

Energy Sector

Power Transmission Lines: Wire rods are used in the production of conductors and cables for power transmission and distribution, ensuring the efficient flow of electricity.

Benefits of Using Wire Rods

Wire rods offer several advantages that contribute to their widespread use across industries:

Versatility: Wire rods can be processed into various forms, such as wires, mesh, and bars, making them suitable for diverse applications.

Strength and Durability: The mechanical properties of wire rods, especially high carbon and alloy steel grades, provide excellent strength and durability, ensuring long-term performance.

Cost-Effectiveness: Wire rods are relatively cost-effective to produce and process, making them an economical choice for many industrial applications.

Adaptability: Wire rods can be customized to meet specific requirements, including different sizes, grades, and surface finishes.

Conclusion

Wire rods are integral to the functioning of numerous industries, providing essential materials for construction, automotive, manufacturing, agriculture, and energy sectors. Their versatility, strength, and adaptability make them invaluable in a wide range of applications. As industries continue to evolve, the demand for high-quality wire rods will remain strong, underscoring their importance in the modern industrial landscape.

0 notes

Text

Same Day Haridwar/Rishikesh Tour By Car

1. Why Choose a Same Day Tour to Haridwar and Rishikesh?

Same Day Haridwar and Rishikesh Tour By Car are two of the most spiritually rich cities in India, located at the foothills of the Himalayas and along the sacred Ganges River. Many travelers opt for a same-day tour due to its flexibility and ease, allowing them to experience both places without an overnight stay. Here’s why a same-day tour is a fantastic choice:

Convenience: Traveling by car ensures a comfortable journey with no need for switching transport.

Flexibility: You control the schedule, allowing you to spend time at the places that interest you most.

Affordability: Avoid the costs of hotel stays, making it a budget-friendly option.

Immersive Experience: Within a day, you can witness the divine rituals of Haridwar and the adventure-filled spiritual ambiance of Rishikesh.

2. Planning the Route and Timings

To make the most of your day, start early in the morning from Delhi or other nearby cities. The distance from Delhi to Haridwar is approximately 220 km, which usually takes around 4–5 hours by car. You can follow this route:

Route: Delhi > Haridwar > Rishikesh > Delhi

Suggested Timings:

5:00 am: Departure from Delhi

9:30 am: Arrival in Haridwar

1:00 pm: Depart for Rishikesh

2:00 pm: Arrival in Rishikesh

6:00 pm: Depart back to Delhi

10:30 pm: Arrival in Delhi

By following this schedule, you’ll have ample time to explore both cities.

3. Key Destinations in Haridwar

Haridwar, often referred to as the "Gateway to the Gods," is one of the holiest cities in India. Known for its ancient temples and the ghats along the Ganges, it’s a place where pilgrims and tourists come together to witness timeless traditions.

Har Ki Pauri

Har Ki Pauri is Haridwar's most famous ghat, known for the Ganga Aarti – a stunning river worship ceremony held in the morning and evening. Watching the oil lamps float on the river as devotees chant creates an unforgettable atmosphere.

Mansa Devi Temple

Dedicated to the goddess Mansa Devi, this temple sits atop the Bilwa Parvat (hill) and can be reached by a short cable car ride. The views from the top offer a panoramic glimpse of Haridwar and the Ganges River, making it a must-visit.

Chandi Devi Temple

This temple is perched on Neel Parvat and is dedicated to Goddess Chandi Devi. It’s another prime spiritual destination, accessible via a ropeway ride that provides beautiful scenic views of the town below.

Bara Bazaar

For those who enjoy shopping, the bustling Bara Bazaar in Haridwar is a treat. You can buy traditional items such as bangles, rudraksha beads, handicrafts, and sweets.

4. Exploring Rishikesh Highlights

After exploring Haridwar, a short drive will take you to Rishikesh, also known as the "Yoga Capital of the World." Nestled along the Ganges and surrounded by forests, it offers a unique blend of spirituality, adventure, and natural beauty.

Laxman Jhula and Ram Jhula

Laxman Jhula and Ram Jhula are two iconic suspension bridges that span the Ganges River. They are bustling with activity, with markets, cafes, and temples on both sides. Walking across these bridges gives you a bird’s-eye view of the holy river and surrounding scenery.

Parmarth Niketan Ashram

One of Rishikesh’s largest ashrams, Parmarth Niketan is famous for its spiritual programs, yoga, and meditation sessions. The evening Ganga Aarti held here is a serene experience, drawing people from all over the world.

Beatles Ashram

Officially known as the Maharishi Mahesh Yogi Ashram, this place became famous after The Beatles visited in 1968. The ashram is now covered in murals and graffiti, making it a quirky and unique spot to explore for music lovers and art enthusiasts.

Adventure Activities

For thrill-seekers, Rishikesh offers exciting activities like white-water rafting, bungee jumping, and ziplining. If you’re up for an adrenaline rush, a quick rafting session on the Ganges is highly recommended.

5. Recommended Itinerary for Same Day Tour

To make the most of your day, here’s a recommended itinerary:

5:00 am: Depart from Delhi

9:30 am: Reach Haridwar and start with Har Ki Pauri

10:30 am: Visit Mansa Devi Temple (via cable car)

11:30 am: Head to Chandi Devi Temple

12:30 pm: Quick shopping spree at Bara Bazaar

1:00 pm: Depart for Rishikesh

2:00 pm: Arrive in Rishikesh and visit Laxman Jhula and Ram Jhula

3:00 pm: Explore Parmarth Niketan Ashram and attend the Ganga Aarti

4:30 pm: Visit Beatles Ashram

5:30 pm: Optional adventure activity (rafting or ziplining)

6:00 pm: Head back to Delhi

10:30 pm: Arrive in Delhi

6. Practical Tips for a Smooth Journey

To ensure your trip goes smoothly, keep the following tips in mind:

Start Early: Leaving as early as possible allows you to avoid traffic and reach Haridwar by mid-morning.

Carry Snacks and Water: Although there are restaurants on the way, having snacks and water on hand can save you time and ensure you’re comfortable.

Dress Modestly: Haridwar and Rishikesh are spiritual places, so wearing respectful attire is advised.

Book Adventure Activities in Advance: If you plan to try activities like rafting in Rishikesh, book them in advance to avoid waiting time.

Stay Hydrated: Both cities can be warm, especially in summer, so staying hydrated is essential.

7. Conclusion

A Same-Day Haridwar/Rishikesh Tour By Car offers a whirlwind yet fulfilling journey through two of India’s most sacred and beautiful cities. With just one day, you can immerse yourself in the spiritual energy of Haridwar, explore the adventure and tranquility of Rishikesh, and create memories that last a lifetime. Whether you’re a spiritual seeker, an adventurer, or someone looking for a refreshing change of pace, this tour promises an unforgettable experience.

0 notes